Moisture Analyzer Max: 50g d: 1mg

0.00SAR

MA 50.X2.AMoisture Analyzer

Maximum capacity [Max]: 50 g

Readability [d]: 1 mg

Readability [d]: 1 mg

Product Details

Specifications

MA 50.X2.A Moisture Analyzer

MA.X2.A series is equipped with innovative system: the drying chamber can be opened and closed automatically using button or proximity sensors.

Such solution allows:

- Maintaining moisture analyzer clean – operator does not touch moisture analyzer’s housing.

- Removing any shocks caused by manual closing of the chamber – the chamber closes automatically and always with the same intensity.

- Achieving high repeatability of opening and closing the drying chamber.

- Enhancing drying process automation.

- Enhancing safety of operation by eliminating contact with hot components of drying chamber.

- Improving operation ergonomics.

MA.X2.A series features user-friendly colour touchscreen. Free configuration of the control panel can be done by means of hotkeys, customizable information fields and programmable labels. Drying process can be carried out for any temperature and – thanks to databases – particular drying process may be set for a specific product.

- Maintaining moisture analyzer clean – operator does not touch moisture analyzer’s housing.

- Removing any shocks caused by manual closing of the chamber – the chamber closes automatically and always with the same intensity.

- Achieving high repeatability of opening and closing the drying chamber.

- Enhancing drying process automation.

- Enhancing safety of operation by eliminating contact with hot components of drying chamber.

- Improving operation ergonomics.

MA.X2.A series features user-friendly colour touchscreen. Free configuration of the control panel can be done by means of hotkeys, customizable information fields and programmable labels. Drying process can be carried out for any temperature and – thanks to databases – particular drying process may be set for a specific product.

Highlights of X2 Series moisture analyzers:

- Automatic opening and closing of the drying chamber

- 5” capacitive colour touchpad

- Modern interface

- Uncomplicated, intuitive operation

- Programmable display

- Drying profiles (standard, mild, step, fast)

- GLP/GMP printouts-reports

- Repeatable and customized applications

- Work optimization due to the use of halogen lamps

- Automatic opening and closing of the drying chamber

- 5” capacitive colour touchpad

- Modern interface

- Uncomplicated, intuitive operation

- Programmable display

- Drying profiles (standard, mild, step, fast)

- GLP/GMP printouts-reports

- Repeatable and customized applications

- Work optimization due to the use of halogen lamps

Capacity and temperature

MA.X2.A maximum capacity ranges from 50g/0.1mg to 210g/0.1mg. Moisture content is measured with the 0.01% accuracy (0.001 % for samples bigger than 1.5g). The maximum drying temperature is 160˚C (there is an optional moisture analyzer with 250˚C maximum temperature).

An additional element for moisture analyzers that improves their functionality is a water vapour permeability determination set used in tanning industry for determining hygienic properties of leather.

MA.X2.A maximum capacity ranges from 50g/0.1mg to 210g/0.1mg. Moisture content is measured with the 0.01% accuracy (0.001 % for samples bigger than 1.5g). The maximum drying temperature is 160˚C (there is an optional moisture analyzer with 250˚C maximum temperature).

An additional element for moisture analyzers that improves their functionality is a water vapour permeability determination set used in tanning industry for determining hygienic properties of leather.

An additional element for moisture analyzers that improves their functionality is a water vapour permeability determination set used in tanning industry for determining hygienic properties of leather.

Databases:

Information system of X2 series moisture analyzers is based on 8 databases, allowing many users to operate product database comprising many samples. Collected measurements may be subjected to subsequent analysis.

Collected data is registered in 8 databases:- Products (up to 5000 products)

- Users (up to 100 users)

- Packaging (up to 100 packagings)

- Customers (up to 1000 customers)

- Drying programs (up to 200 drying programs)

- Drying process reports (up to 5000 drying process reports)

- Ambient conditions (up to 10000 records)

- Weighings (up to 50000 records)

Information system of X2 series moisture analyzers is based on 8 databases, allowing many users to operate product database comprising many samples. Collected measurements may be subjected to subsequent analysis.

Collected data is registered in 8 databases:

Collected data is registered in 8 databases:

- Products (up to 5000 products)

- Users (up to 100 users)

- Packaging (up to 100 packagings)

- Customers (up to 1000 customers)

- Drying programs (up to 200 drying programs)

- Drying process reports (up to 5000 drying process reports)

- Ambient conditions (up to 10000 records)

- Weighings (up to 50000 records)

The results

The results obtained using the moisture analyzer (the final result of the drying process):- % M – the mass loss in %; displays the mass change recorded during the drying process, expressed as a percentage,

- % D – the dry mass obtained during the drying process, expressed as a percentage; the result is the portion of the sample that remains on the weighing pan after the moisture has evaporated,

- % R – the ratio of moisture content to dry mass, obtained during the drying process, expressed as a percentage; the result is the portion of the sample that evaporated during the drying process,

- g – the sample mass after drying.

The results obtained using the moisture analyzer (the final result of the drying process):

- % M – the mass loss in %; displays the mass change recorded during the drying process, expressed as a percentage,

- % D – the dry mass obtained during the drying process, expressed as a percentage; the result is the portion of the sample that remains on the weighing pan after the moisture has evaporated,

- % R – the ratio of moisture content to dry mass, obtained during the drying process, expressed as a percentage; the result is the portion of the sample that evaporated during the drying process,

- g – the sample mass after drying.

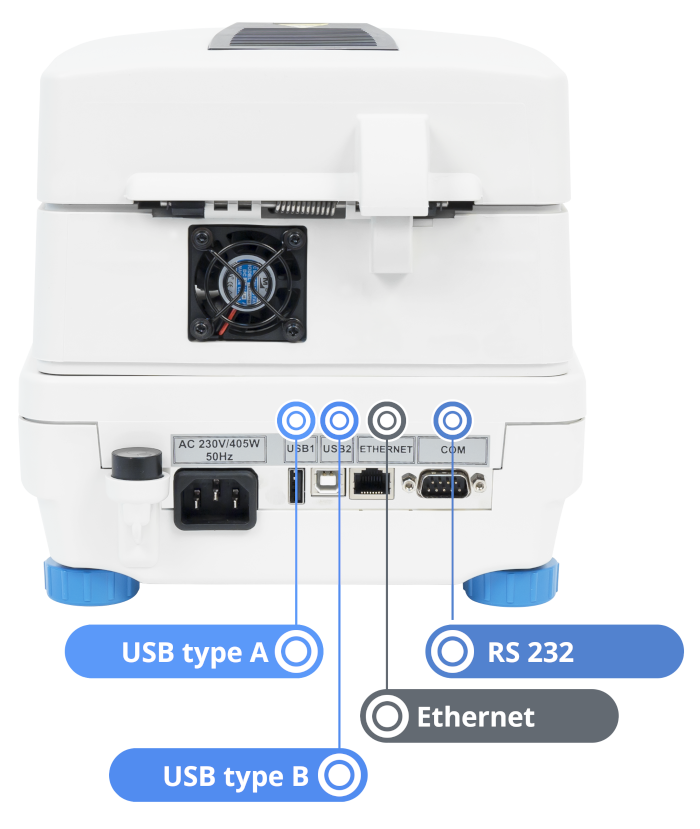

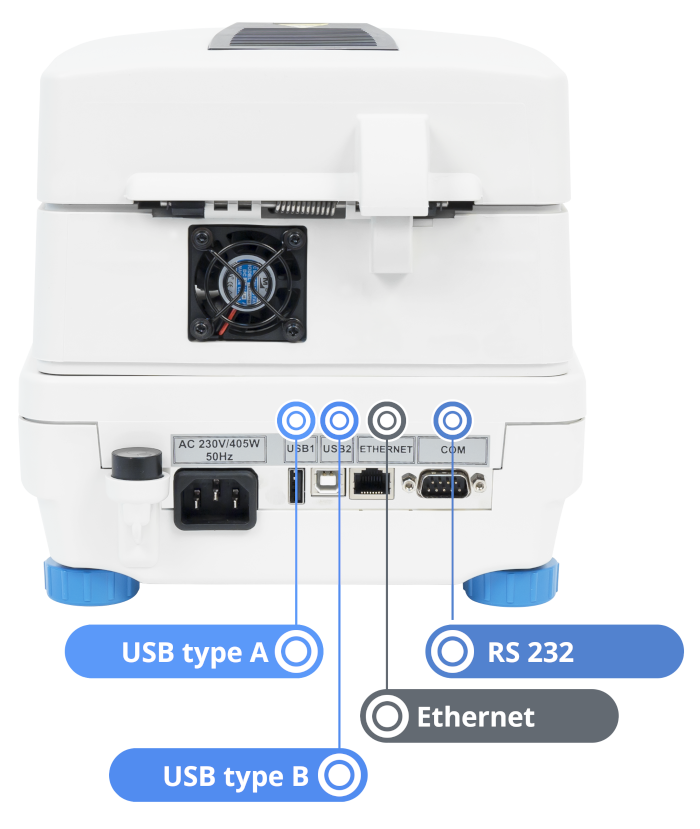

Interfaces

USB interface ensures quick transfer and copying of any results of your work (measurements, reports, databases) to a computer or other moisture analyzer.

Remote access to the moisture analyzer allows for online data management.

Cooperation with E2R allows for external data management which in turn increases the efficiency and results to the maximum.

USB interface ensures quick transfer and copying of any results of your work (measurements, reports, databases) to a computer or other moisture analyzer.

Remote access to the moisture analyzer allows for online data management.

Cooperation with E2R allows for external data management which in turn increases the efficiency and results to the maximum.

Remote access to the moisture analyzer allows for online data management.

Cooperation with E2R allows for external data management which in turn increases the efficiency and results to the maximum.

Balance

- Maximum capacity [Max]50 g

- Readability [d]1 mg

- Tare range-50 g

- Adjustmentexternal

- Leveling systemmanual

- Display5” graphic color touchscreen

- Net weight5.16 kg

- Gross weight6 kg

- Maximum sample weight50 g

- Heating moduleIR emitter

- Moisture content readability0.001%

- Protection classIP 43

- Weighing pan materialø90, h= 8 mm

- Finish mode4 modes (automatic, manual, time-defined, user-defined)

- Moisture content repeatability+/-0.05% (sample ~ 2g), +/-0.01% (sample ~ 10g)

- Drying temperature rangeMax 160 °C

- Weighing chamberautomatic

- Maximum sample height20 mm

- Additional functionssample traceability

- Power consumption6 W

- Heating module power450 W

- Mass indication controlExternal mass standard 50 g, 100 g, 200 g (depending on the type of moisture analyzer)

- Internal adjustmentFor .IC models only, GLP report

- External adjustmentFor all models, GLP report

- Drying temperature controlOne- or two-point, depending on the drying profile (equipment: GT105k-12/Z Control Thermometer)

- Moisture content indication controlCertified MV Test Set

- Internal / External adjustmentDepending on the type of moisture analyzer, GLP report